June 2019 - LIFE DIANA

Α) Identity of the project

| Title/ N° |

LIFE DIANA - Development of a pilot unit for the valorization of petroleum refinery sludges to new added-value raw materials (LIFE 16 ENV/GR/000461) |

| Duration |

01/07/2017 – 30/6/2020 |

| Budget |

2.051.585 € (Total cost) |

|

Beneficiaries |

Coordinating Beneficiary: Associated Beneficiaries: |

| Location of activities |

Greece (Corinth, Attica) |

| Website | |

| Contact |

Michalis Pachnos |

Description/Aim

The LIFE DIANA project addresses one of the most important environmental challenges faced by the Greek and European petroleum refining industry, which is the treatment and end-of-life management of petroleum refinery sludges (PRS), the final by-product from crude oil processing when producing fuels and other valuable petroleum products. In Greece, the petroleum refineries produce approximately 34.000 tons of PRS annually while in Europe are estimated to around 1.000.000 tons per year.

Due to the complex and inconstant composition of PRS, cost-effective treatment and proper end-of-life management pose considerable technical and industrial challenges worldwide.

The main purpose of the project is the innovative processing and stabilization of the PRS with the use of industrial minerals in order to develop an Engineered Soil, suitable as landfilling material.

Β) Best Practices

In the framework of LIFE DIANA project, it is foreseen:

- Development of new innovative materials and processes for the PRS exploitation into a useful product (Engineered Soil) in the life/economic cycle.

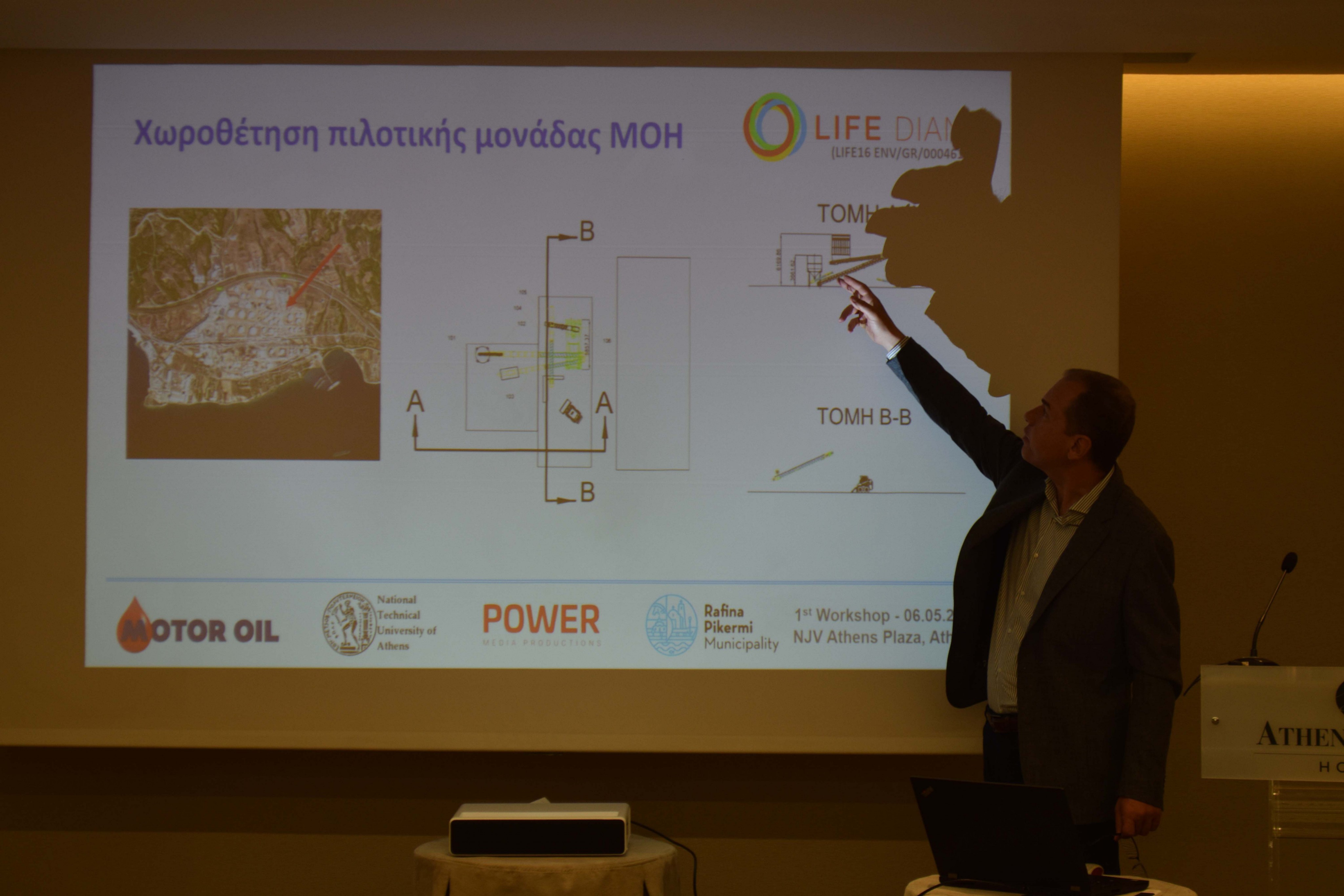

- Design and construction of a pilot plant for the mixing of the PRS with low-cost industrial materials, which are abundant in Greece and the EU.

- Pilot trial stabilization, at industrial scale, using PRS produced in MOTOR OIL Refineries by using the suggested innovative materials and processes.

- Production of a valuable Engineered Soil from the pilot plant of MOTOR OIL, which complies with the mechanical and physicochemical properties of landfilling materials.

- Pilot application of the Engineered Soil as landfilling material.

- Measurement of environmental behavior and comparative assessment of the Engineered Soil in real landfilling conditions.

- Development of multiple dissemination actions focusing on the general public. Tools to be used are: project website, public notice boards, leaflets, newsletters, dissemination videos and promotion through the social networking tools (LinkedIn and Twitter).

- Creation of dissemination actions for the specialized stakeholders of LIFE DIANA project (targeted seminars, pilot plant visits, scientific announcements, workshops, etc.).

C) Results

Within the project the following actions have already been achieved:

- Extensive experimental exploration of the appropriate industrial minerals that could be used for PRS stabilization.

- Wide laboratory analysis of the PRS physicochemical properties.

- Experimental development and simulation of PRS stabilization conditions with the optimum industrial minerals and scientific analysis of the overall process.

- Detailed design and engineering of the pilot PRS stabilization process to Engineered Soil.

- Research and analysis of the European and Greek legislation regarding the physicochemical properties of landfilling bottom, daily and top cover materials.

- Pilot design and benchmarking in real conditions of Engineered Soil in landfills.

- Supply and installation of machinery and consumables for the two pilot sites of LIFE DIANA, in MOTOR OIL refineries and in landfill.

- Development of technical, environmental, economic and social KPIs (Key Performance Indicators) and definition of their measurement protocol.

- Market analysis of raw materials and products related to the PRS stabilization process.

- Extensive promotional activities of the LIFE DIANA project through the project website, notice boards, leaflets, newsletters, video social media accounts ((LinkedIn and Twitter), workshops and scientific presentations.

With the successful completion of the project, the following actions are expected to be implemented:

- Stabilization of 1.500 tn PRS, thus producing 3.000 tn Engineered Soil.

- Pilot application of the Engineered Soil in landfilling and assessing its environmental behavior under real conditions.

- Development of a business model in order to investigate the financial sustainability of the innovative LIFE DIANA process.

- Life-Cycle Cost and Assessment (LCC-LCA) of LIFE DIANA technology.

- Project monitoring through well-defined KPIs.

- Extension of actions that have already started on the basis of the strategic dissemination plan of the project (website, leaflets, newsletters, video, social media, seminars, pilot visits, scientific publications, workshops, etc)

After the completion of the project, the following actions are expected to be implemented:

- The LIFE DIANA technology can be exploited by the Greek and European petrochemical industry, as 30.000 tons per year of PRS are produced in Greece, while in Europe 1.000.000 tons per year.

- Exploitation of the produced Engineered Soil as landfilling material by the solid waste management associations within Greece and Europe.

- Use of Engineered Soil in restoration and rehabilitation/revegetation of abandoned lands (e.g. quarries).

- Application of the technology and the stabilization materials in other industrial based by-products.

- Promotion of the “Circular Economy” European policy.

- Information of the general public and targeted stakeholders about LIFE DIANA project and its results, co-funded by the European LIFE Programme.